Service Needs for a Commercial Trash Compactor

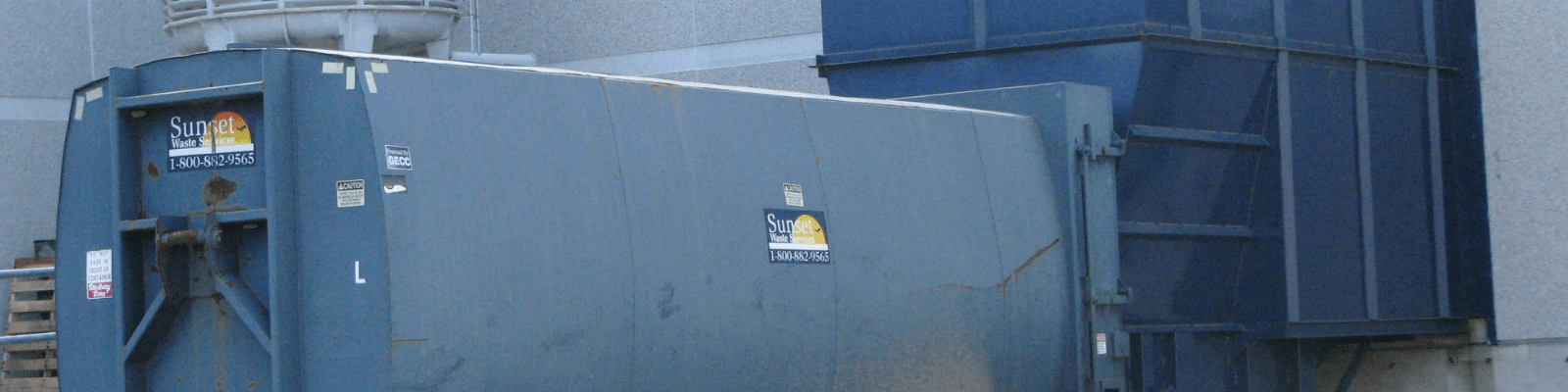

Your commercial trash compactors are a great investment for your businesses that generate a large volume of recycling materials and/or waste. By crushing and compressing waste, fewer hauls are required, which lowers your collection and transportation costs for your recycled materials.

Your commercial trash compactor works hard and is used regularly in all kinds of extreme environments. And like all heavy equipment, there are hydraulic systems, switches, controls, and electrical systems- also a constant abrasion of metal against metal. Because of all of these factors, commercial trash compactors may need repairs and maintenance checks from time to time to make sure everything is working properly.

Let’s go over some common service needs for commercial trash compactors.

1. Loud / Strange Noises

This is one of the most common problems that result in your commercial trash compactor needing service. You probably already know that commercial trash compactors are already loud machinery to begin with. However, if the noises coming from your machine become strange or even louder than normal, then there could be a bigger problem with the compactor that requires attention. There could be several causes behind this situation, which is why it is recommended to get your machine checked out by a service professional.

2. The Ram Won't Move

The ram is a key part of the compactor. It is responsible for compacting the materials inside the machinery, so it must operate correctly for the compactor to run efficiently. If this is not happening, then there could be several issues with different parts of the compactor. For example, the power nut, directional switch, or driver gear. A recycling equipment repair company will be able to inspect and find the cause of this problem.

3. The Compactor Doesn't Turn On

This is another common issue with your compactor that will require servicing. Sometimes, the cause behind this issue is as simple as fixing a power cord or circuit breaker. However, it could also be an issue with the drive motor and directional switch.

4. The Compactor Won't Stop

Once the cycle is complete, your compactor should come to a complete stop. It should not continue running after compacting all the materials inside. However, sometimes the compactor will continue to run even after the session is complete. If this happens, you will want to inspect the compactor’s start switch and the directional switch. If the problem continues, then you should take it in to get inspected.

5. The Compactor Won't Stay On

The commercial trash compactor must stay powered on throughout the whole cycle in order to be completed. If it turns off at any point in the cycle, then it could cause issues, as the materials won’t be compacted all the way through. If this occurs, it’s highly recommended to get in contact with a professional compactor repair specialist. These individuals will have the necessary equipment, experience, and tools to repair your compactor in an efficient and timely manner.

Speed-Tech Equipment Can Help!

Speed Tech Equipment is a provider of recycling equipment, based in Hudsonville, Michigan. We sell and service every piece of equipment necessary. Everything from balers to compactors, to Shredders and Conveyors. We also offer recycling equipment parts and expert service throughout Michigan and parts of Indiana and Ohio.

To Learn More Check Out Our Baler & Compactor Services