Loading Dock Equipment 101: A Comprehensive Guide

Loading dock equipment is a critical component of logistical operations, serving as the interface between vehicles and the warehouse or facility. It encompasses a variety of tools and machinery designed to facilitate the efficient and secure loading and unloading of goods. Common elements include dock levelers, dock seals, vehicle restraints, and dock lights.

The significance of selecting appropriate loading dock equipment cannot be overstated, as it directly impacts the efficiency, safety, and cost-effectiveness of logistical operations. Investing in well-matched equipment enhances productivity by streamlining loading and unloading processes, reducing downtime, and minimizing the risk of damage to goods or equipment. The right equipment also contributes to workplace safety, preventing accidents and injuries associated with loading and unloading activities.

Let’s delve into the details and explore the process of selecting the right loading dock equipment!

Dock Levelers

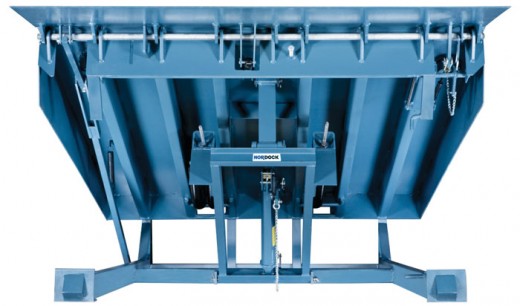

Dock levelers are pivotal components in loading dock equipment, serving to bridge the height disparity between a vehicle and the dock. They facilitate the seamless transfer of goods by creating a level surface, allowing forklifts and personnel to move efficiently and safely between the dock and the vehicle. Dock levelers are typically hydraulically or mechanically operated, adjusting to the varying heights of trucks and ensuring a smooth transition during loading and unloading activities.

Types of Loading Dock Levelers

Hydraulic Levelers

Utilize hydraulic systems for smooth and controlled vertical adjustment.

Offer precision in positioning, adapting to different truck bed heights.

Known for durability and minimal maintenance requirements.

Mechanical Levelers

Operate through a system of springs and hinges for vertical adjustment.

Cost-effective option with reliable performance.

Suitable for moderate loading and unloading volumes.

Air-Powered Levelers

Use airbags for vertical adjustment, providing a cushioned and controlled descent.

Ideal for facilities requiring a low-maintenance solution.

Suitable for a range of loading dock applications.

Key Features to Consider

Weight Capacity

Assess the weight-bearing capacity of the dock leveler to accommodate varying loads.

Dimensions

Consider the size of the dock leveler to match the dimensions of commonly serviced vehicles.

Safety Features

Prioritize features such as lip extension, safety barriers, and automatic lip deployment for enhanced safety during operations.

Durability

Evaluate the construction materials for durability, corrosion resistance, and longevity.

Maintenance

Opt for dock levelers with minimal maintenance requirements to ensure operational efficiency over time.

Loading Dock Seals and Shelters

The primary function of dock seals and shelters is to create a secure and weather-resistant enclosure between a loading dock and a trailer, fostering a controlled environment during the loading and unloading processes. By forming a seal around the trailer, these structures prevent the ingress of external elements such as rain, snow, and wind, enhancing overall operational efficiency. Additionally, dock seals and shelters contribute to workplace safety by minimizing the risk of accidents and injuries associated with unpredictable weather conditions.

Compression Dock Seals

Description: These seals tightly envelop the trailer, creating a secure barrier against external elements.

Function: Effective weather protection during loading and unloading.

Application: Suitable for various cargo types and environments.

Inflatable Dock Shelters

Description: Utilize airbags to create a flexible seal around the trailer.

Function: Accommodate variations in trailer sizes, ensuring a snug fit.

Application: Ideal for facilities with diverse trailer dimensions.

Rigid Frame Shelters

Description: Typically made of steel or aluminum for durability.

Function: Provide a robust and reliable enclosure, suitable for high-traffic loading docks.

Application: Commonly used in demanding environments where structural integrity is crucial.

Vehicle Restraints

Vehicle restraints serve the fundamental purpose of enhancing loading dock safety by preventing unintended trailer movements during the loading and unloading process. They function as a critical component in securing trucks and trailers to the dock, reducing the risk of accidents caused by premature departures or unexpected shifts. The primary objective is to create a stable and controlled environment, ensuring the safety of both personnel and equipment operating in proximity to the loading dock.

Wheel Chocks

Physical blocks are placed against the wheels to prevent motion.

Automatic Hook Restraints

Engage with the trailer’s rear impact guard, securing it automatically.

Manual Barrier Restraints

Require manual deployment and connection to the trailer.

Hydraulic Vehicle Restraints

Utilize hydraulic systems to secure the trailer firmly in place.

Loading dock safety is significantly enhanced through the implementation of vehicle restraints. By preventing accidental trailer movements, these restraints contribute to a controlled environment, reducing the potential for collisions and injuries. The use of modern, automated restraints ensures efficient and reliable engagement, minimizing human error and enhancing overall operational safety. Regular maintenance and compliance with industry safety standards further reinforce the effectiveness of vehicle restraints in promoting a secure loading dock environment.

Conclusion

Throughout the discussion, we’ve explored essential aspects of loading dock equipment, including the role of dock seals, shelters, and vehicle restraints. Each component serves a specific purpose in creating a secure, controlled, and efficient loading dock environment. Whether it’s preventing the ingress of external elements, securing vehicles to the dock, or facilitating vertical transitions, these elements collectively contribute to streamlined material handling operations.

Final Tips for Choosing the Right Loading Dock Equipment

- Assess Operational Needs: Understand the unique requirements of your facility, considering factors like load capacity, frequency of use, and environmental conditions.

- Compliance with Safety Standards: Prioritize equipment that adheres to industry safety standards, ensuring a secure working environment and regulatory compliance.

- Consider Future Growth: Choose equipment that accommodates potential changes in your operations, allowing for scalability and adaptability.

- Regular Maintenance: Implement a proactive maintenance schedule to extend the lifespan of your loading dock equipment and prevent unexpected breakdowns.